Aerated or foam concrete? What’s better?

Quite often when you use cellular concrete in construction, you keep asking yourself: aerated or foam concrete? What’s better?

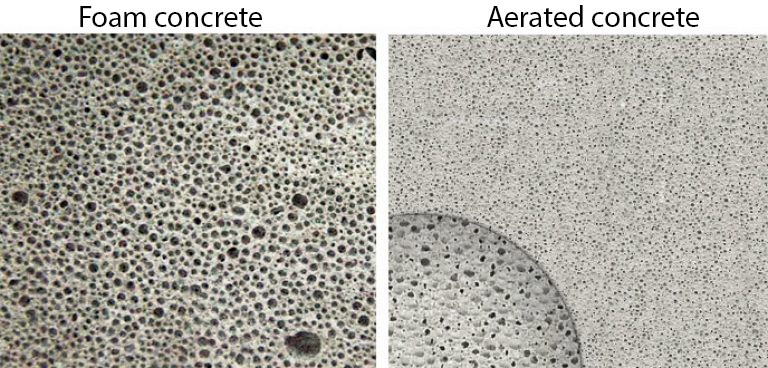

Aerated concrete and foam concrete belong to the cellular concrete category, the properties of them both are subject to GOST 25485-89, while their gross difference lies in their manufacturing technology. When aerated concrete is being manufactured, the porous structure of concrete is formed with the help of gas bubbles being the result of a chemical reaction between cement and aluminum powder contained in the gas-forming agent. The porous structure of the material is preserved while the aerated concrete is solidifying. When the strength is gained, the material we get is light and durable, which conserves heat quite well.

When manufacturing foam concrete, the porous structure is formed with the help of air bubbles uniformly distributed throughout the cement mixture. The presence of air bubbles in foam concrete is ensured by feeding foam into the cement mixture or by adding a foaming agent into the cement mixture while mixing. When the material is solidified, the porous structure is preserved. Foam concrete compared to aerated concrete has a closed-cell structure which ensures less moisture absorption.

However, foam or aerated concrete walls are usually not left uncovered, but protected from the environmental exposure effect with the help of plaster, siding, finish tiles, etc. At a construction site, not only thermal insulation properties, but the compression breaking strength is of importance. Foaming agents (especially the synthetic ones) which are used for making foam concrete have negative influence on the strength of a cement brick. To make a load-bearing wall, bricks of at least B2 class of compression breaking strength should be used.

In order to ensure such strength in foam concrete, the material density should be at least 700-800 kg per cu. m. The same class of strength (B2) in aerated concrete can be achieved with the density of 500-600 kg per cu. m.So, aerated concrete can be considered as a stronger material. Thanks to the same reason, foam concrete is more expensive to manufacture than aerated concrete. Just to compare: the cement consumption for manufacturing 1 cu. m of foam concrete with the density of 800 kg per cu. m is at average 380-400 kg, while for manufacturing 1 cu. m of aerated concrete with the density of 600 kg per cu. m you will require only 280-300 kg of cement. Also it is worth mentioning that a wall made of aerated concrete with the density of 600 kg per cu. m can be thinner having the same strength and thermotechnical properties.

Anyway, it is the consumer who will choose the material. Before buying, you need to make sure that the material chosen corresponds to the GOST requirements and to study the peculiarities of material use and its further operation.

Aerated concrete and foam concrete belong to the cellular concrete category, the properties of them both are subject to GOST 25485-89, while their gross difference lies in their manufacturing technology. When aerated concrete is being manufactured, the porous structure of concrete is formed with the help of gas bubbles being the result of a chemical reaction between cement and aluminum powder contained in the gas-forming agent. The porous structure of the material is preserved while the aerated concrete is solidifying. When the strength is gained, the material we get is light and durable, which conserves heat quite well.

When manufacturing foam concrete, the porous structure is formed with the help of air bubbles uniformly distributed throughout the cement mixture. The presence of air bubbles in foam concrete is ensured by feeding foam into the cement mixture or by adding a foaming agent into the cement mixture while mixing. When the material is solidified, the porous structure is preserved. Foam concrete compared to aerated concrete has a closed-cell structure which ensures less moisture absorption.

However, foam or aerated concrete walls are usually not left uncovered, but protected from the environmental exposure effect with the help of plaster, siding, finish tiles, etc. At a construction site, not only thermal insulation properties, but the compression breaking strength is of importance. Foaming agents (especially the synthetic ones) which are used for making foam concrete have negative influence on the strength of a cement brick. To make a load-bearing wall, bricks of at least B2 class of compression breaking strength should be used.

In order to ensure such strength in foam concrete, the material density should be at least 700-800 kg per cu. m. The same class of strength (B2) in aerated concrete can be achieved with the density of 500-600 kg per cu. m.So, aerated concrete can be considered as a stronger material. Thanks to the same reason, foam concrete is more expensive to manufacture than aerated concrete. Just to compare: the cement consumption for manufacturing 1 cu. m of foam concrete with the density of 800 kg per cu. m is at average 380-400 kg, while for manufacturing 1 cu. m of aerated concrete with the density of 600 kg per cu. m you will require only 280-300 kg of cement. Also it is worth mentioning that a wall made of aerated concrete with the density of 600 kg per cu. m can be thinner having the same strength and thermotechnical properties.

Anyway, it is the consumer who will choose the material. Before buying, you need to make sure that the material chosen corresponds to the GOST requirements and to study the peculiarities of material use and its further operation.

+7 913-923-66-02

+7 913-923-66-02